Due to various factors (such as friction, uneven temperature or roll deformation, etc.) resulting in uneven deformation of rolled parts, internal stress will be caused in the metal.The internal stress produced in the rolling process of metal is called additional stress; The additional stress remaining in the metal after rolling is called residual stress.

If there is residual stress in the steel plate, it will affect the mechanical properties of the steel plate, but also easy to lead to plate shape problems, and in serious cases, it will produce cracks or broken and cause waste products.

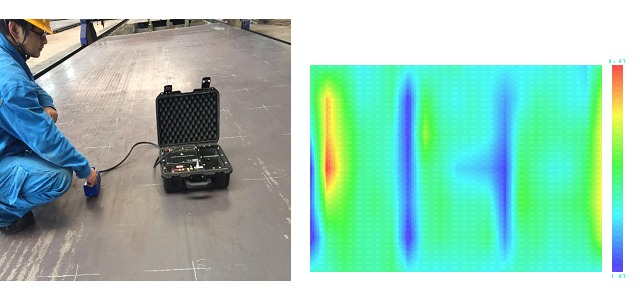

Hysteresis nondestructive evaluation technology can quickly reflect the stress distribution of steel plate without grinding clean steel plate, and can be used for steel plate shape control and process adjustment.

Please contact us for details:

18911495815

010-85778110