Introduction:

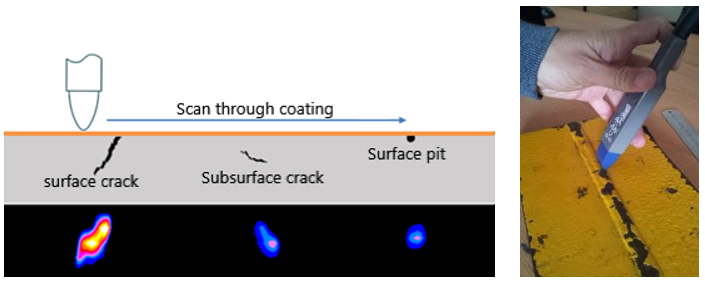

LIZARD is primarily used for the detection and sizing of surface breaking fatigue defects in metallic structures/components combined with the ability to ‘see through’ protective coatings

First developed in 1989 as a response to industry major requests for non-invasive inspection through protective coatings as an alternative to dye based methods, the Lizard provides for AC Field Measurement, Classic Phase Plane, 3 Dimensional, C Scan acquisition and display modes from a single array pass – this made possible by the unique Field Gradient Imaging IPR employed within the LIZARD technology

The Lizard technology is completely non-invasive and environmentally friendly with the data presented providing for comprehensive analysis including sizing for length and depth using acquired data only

Due to the ability to utilize the varying electro-magnetic techniques in a single data set the Lizard can combine the responses to provide for advanced configuration and /or analysis options

LIZARD technology is available for both topside and subsea inspection campaigns including robotically deployed systems.

Principle

Application