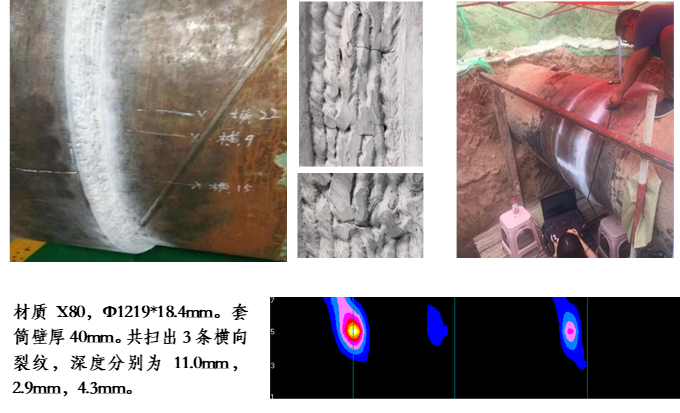

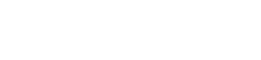

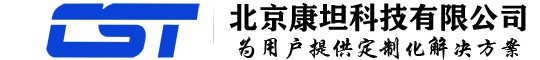

The B-type sleeve fillet welds of long-distance oil and gas pipelines often have delayed cracks. However, due to the complex structure of fillet welds, ultrasonic and gamma rays cannot be detected, and magnetic particle and penetration cannot measure the depth of cracks.

FGI technology can save the cost and time of polishing the coating, and can measure the depth and length of the crack information, which provides an effective basis for the safety evaluation of long-distance pipeline.