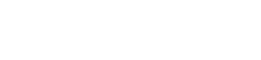

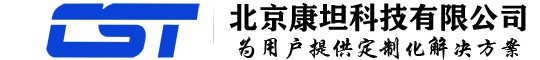

In the rolling process, the steel plate is affected by the composition, technology and other factors, and the distribution of internal stress is not uniform, resulting in buckling or deformation after cutting. The non-destructive hysteresis evaluation technique can effectively evaluate the internal stress distribution of steel plate and has important guiding significance for rolling and straightening processes.

Our company was commissioned by a steel mill in China, using non-destructive hysteresis assessment technology to evaluate the internal stress of a batch of steel plates. Steel plate material: pipeline steel L485, specification: 20×2470×12150mm

Hysteresis nondestructive assessment technology can be measured directly on the workpiece surface without grinding the surface, no coupling, up to 6mm lifted, data acquisition only 3 seconds, data can be stored in real time, built-in software can map the coercivity color distribution, red areas represent danger areas (i.e., high stress areas).